Todays homeowners pay a lot of hard earned dollars to heat and cool their homes and I know you Massachusetts and New Hampshire residents would love to cut the high costs of conditioning your homes. With the continuous rise in heating fuel costs, the only ideal way to cut these costs is to locate and seal those breached areas of your home that are stealing your energy dollars daily. If you are able to retain the conditioned air (inside your home) for a longer period of time, you will be spending much less money on fuel and electricity that is powering your heating and air conditioning system. In a typical home, space conditioning and comfort bills can account for up to one-half of your home's energy bills, with the remaining portion due primarily to heating your domestic water, interior lighting, and your appliances. Knowing that space conditioning accounts for half of your energy bills, I can show you how you can lower this expense now.

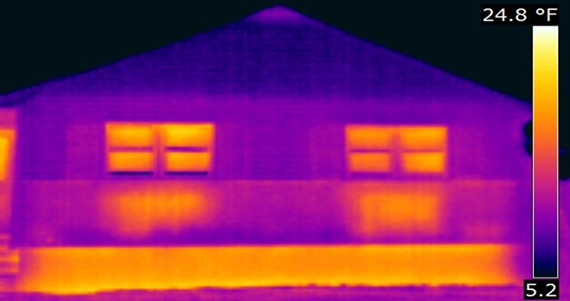

What you need is an infrared inspection! An infrared inspection is a brilliant method of providing you with an instant snapshot of active energy losses through the interior walls and ceilings of your home. Thermal imaging will visually show thermal mapping of any damaged, settled or improperly insulated cavities throughout your home. Appreciable temperature differences, (due to variations in thermal energy heat transfer) allow me to determine the adequacy and proper installation of the concealed insulation that is installed throughout your structure's exterior wall and ceiling cavities. I’m able to detect obvious insulation issues while thermally scanning your exterior ceiling and wall surfaces. Deficient insulation is a poor insulator, which makes it a great conductor of your conditioned air, and this is what enables me to easily detect the thermal anomalies in these areas. Any major differentials in surface temperature are going to be the obvious areas that are going to require you to upgrade insulation, in order for you to start saving your energy bucks.

Keep in mind that there are always going to be minor air breaches in typical exterior walls and ceilings, due to wood structural members that will conduct exterior air at the structural transitions and simply can not be insulated. But, I would like to walk you through your home and literally show you the major areas of concern where excessive air is infiltrating your conditioned living area, causing your energy bills to become sky high.

After pointing out the inefficient areas of your home that need to be improved, I will be providing you with a comprehensive

professional IR report which will be highlighting those areas of concern that are in need of an insulation upgrade now. You can then utilize my infrared report as a guide to locate the exact areas of concern when applying the insulation or simply hire an insulation contractor who will be able to utilize my Infrared report as a guide to locating and upgrading the insulation defects and fissures throughout your home.

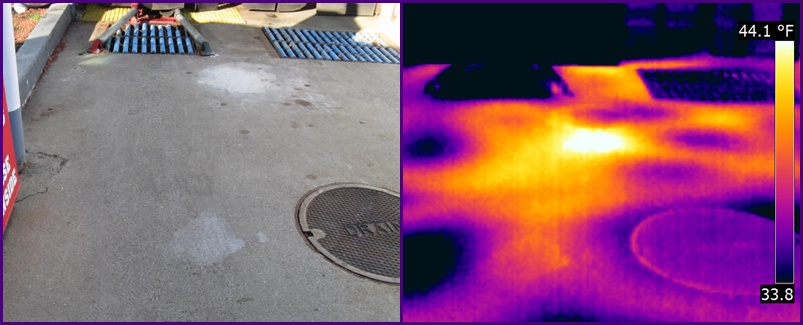

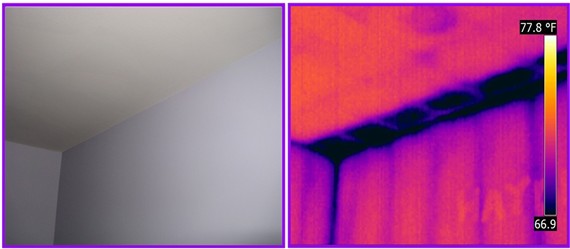

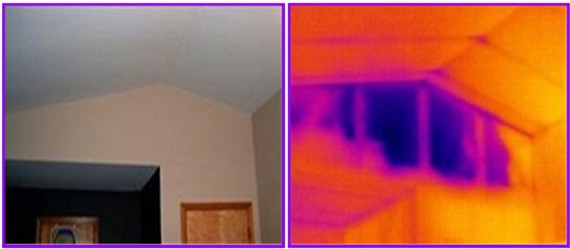

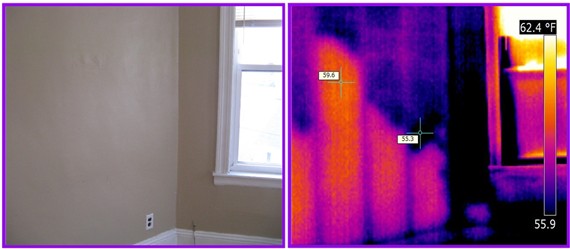

Take a look at many concealed insulation breaches that infrared can detect...

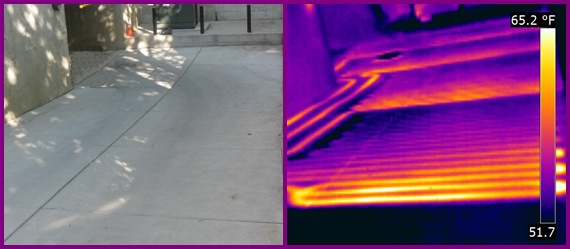

A visual inspection of this ceiling indicates that nothing is wrong, but my thermal scan reveals missing insulation throughout the outer rim board area.

This wall looks fine until my infrared camera detects settled insulation

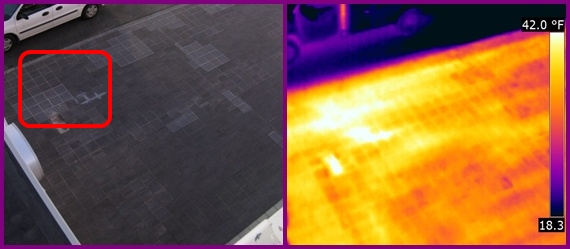

This children's room looks fine visually, but my infrared camera reveals missing insulation throughout another rim board wall cavity.

Visually, this wall appears to be in great shape, but my infrared scan detects missing insulation behind this attic knee space. This cold air infiltration is as bad as leaving a window ajar.

I was hired to inspect a recent installation of blown-in insulation. Visually, it looks fantastic, but infrared reveals shoddy workmanship.

The outer ceiling cavities in this bedroom were not insulated.

SPRAY FOAM INSULATION

There is a rumor (throughout the insulation market) that spray foam insulation is the best insulation on the market today. The manufacturers of this innovative product claim that the foam is energy efficient, environmental friendly, and they also claim that it will fully expand and completely fill all cracks, crevices, and voids. They also claim that foam insulation creates an effective air tight seal which guards against air infiltration, which is the number one source of energy loss in a structure.

Well, most of today's foam insulation may be environmental friendly, but I can say (from experience) that foam insulation is not the perfect insulation and it never will be, unless the foam insulation installer has their foam application verified with an infrared scan. I've performed many infrared inspections on newly constructed homes containing foam insulation and I have never come across a perfect foam insulation application yet. There will be imperfect applications due to the air bubbles that develop within the foam (as it's expanding) and these voids will allow exterior air to infiltrate your living area. An infrared scan will detect these voids and the foam insulation applicator can then apply additional foam to these areas in order to obtain that air tight seal that is required for an energy efficient home.

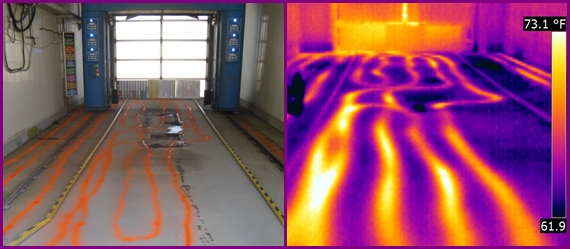

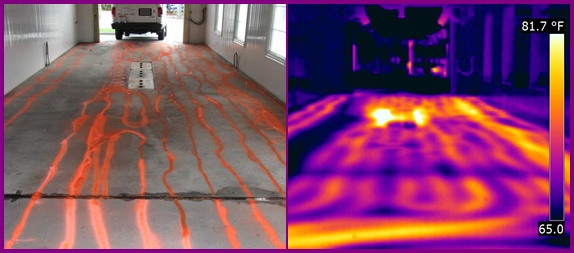

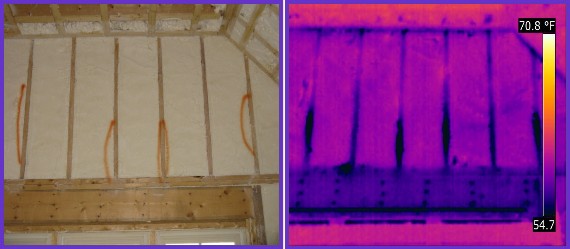

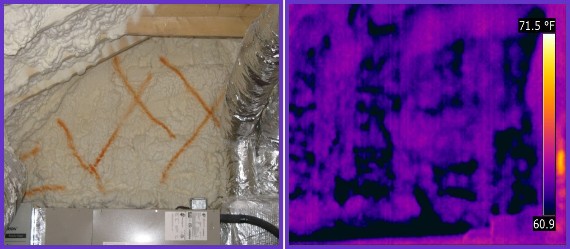

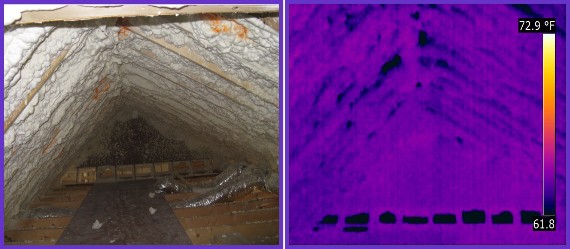

Take a look at these images of a foam insulation application before the drywall was installed. A local building contractor utilized my infrared services to verify that there were "NO voids" within the thick foam insulation that was applied into the ceiling and wall cavities of the structure. They were seeking peace of mind before they installed the drywall and my infrared scan easily detected minor voids that they simply marked and upgraded during my thermal scan.

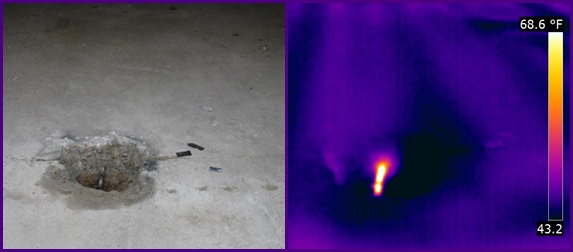

This foam insulation did not form a tight seal at the lower portion of these wall studs. The top portion of this wall looks great.

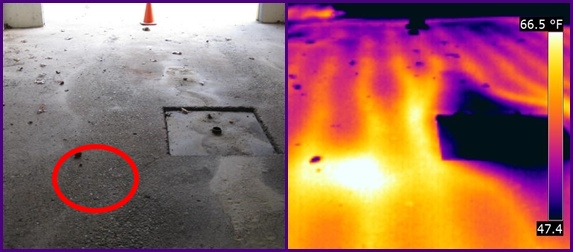

Note the excessive voids throughout this entire foamed-in wall.

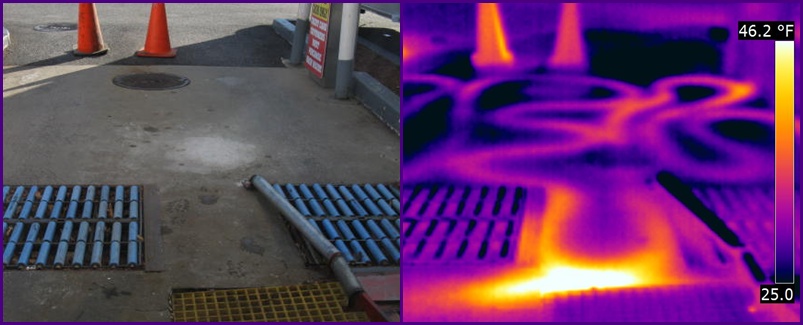

The foam insulation in this attic cavity looks pretty good, until infrared detects minor inefficiencies.

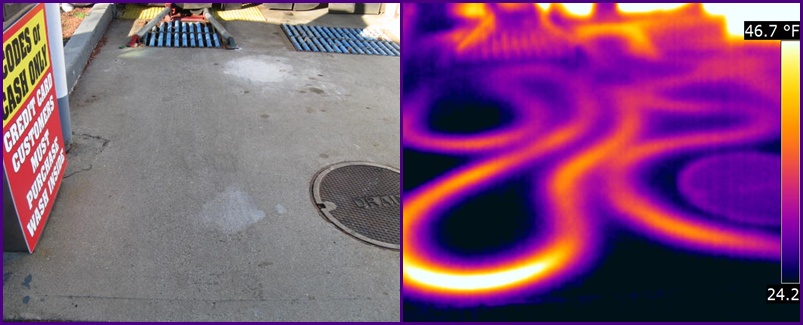

This particular foam application is flawless, which is a rare occasion.